The research project will use the Institute for Computational and Data Sciences’ ROAR supercomputer. IMAGE: PENN STATE

$1.2 million grant to develop high-temperature alloys for gas turbines

Posted on December 8, 2020UNIVERSITY PARK, Pa. — An integrated computational and experimental framework for the design and manufacturing of ultrahigh-temperature refractory alloys may become possible thanks to a $1.2 million grant from the U.S. Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E) awarded to a team of Penn State materials scientists.

The team, led by Zi-Kui Liu, professor of materials science and engineering, received the grant as part of $16 million in funding recently awarded for 17 projects through ARPA-E’s Ultrahigh Temperature Impervious Materials Advancing Turbine Efficiency (ULTIMATE) program. ULTIMATE teams will develop ultrahigh temperature materials for gas turbine use in the aviation and power generation industries.

“Natural gas turbines generate more than a third of the country’s electricity, supplying power to consumers across America,” said ARPA-E Director Lane Genatowski. “ULTIMATE teams will improve the efficiency of the generation sector by developing materials that increase producers’ efficiency and create positive economic benefits for industrial and public consumers nationwide.”

Refractory alloys have desirable mechanical properties, like high yield strength and fracture toughness, particularly at high temperatures, making them potential candidates for structural applications. Knowledge on the atomic and electronic interactions are important to enable development of a predictive approach for rapidly designing advanced materials.

Liu, who was recently named the inaugural Dorothy Pate Enright Professor, will lead the team to generate alloy property data using high-throughput computational and machine learning models and design ultrahigh-temperature refractory alloys employing a neural network inverse design approach, where the needed functionality and property are specified first, followed by identification of the materials that exhibit the desired properties.

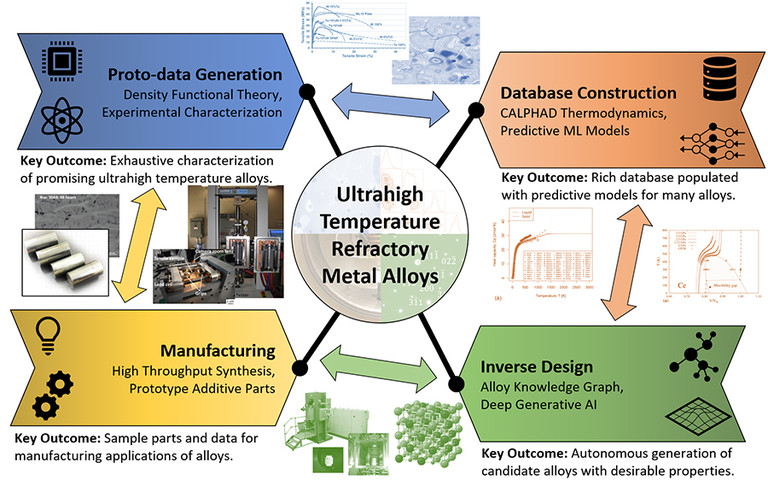

The project framework consists of following major components:

- Computational data generation through high throughput first-principles calculations based on the density functional theory, deep neural networks machine learning models, crystal plasticity finite elements method simulations and high throughput Calculation of Phase Diagrams (CALPHAD) modeling of phase stability

- Inverse design of ultrahigh temperature refractory alloys (ULTERAs) using both computational and experimental data and the strengthening and toughening mechanisms

- Advanced manufacturing techniques utilizing field assisted sintering technology

- Systematic characterization to demonstrate performance in terms of mechanical and thermal properties of the designed materials in collaboration with industry

The proposed platform with a sustainable data ecosystem could create fundamentally new approaches to understand and designing a new generation of materials and provide pathways to improve existing materials to meet performance requirements.

In addition to Liu, other members of the team are Assistant Professor Wesley Reinhart, Associate Professor Allison Beese, Professor Shashank Priya and Research Professor Shun-Li Shang from the College of Earth and Mineral Sciences’ Department of Materials Science and Engineering; and Research Professor Jogender Singh and Associate Research Professor Ted Reutzel from the Applied Research Laboratory at Penn State.

Share

Related Posts

- Supercomputer cluster donation helps turn high school class into climate science research lab

- Former IST doctoral student oversees software development and research at Adobe

- IBM donates system to Penn State to advance AI research

- Supercomputer needs a super name: Join the supercomputer naming contest